The values should not be under 240 and above 300, but there is no single ideal value. If you have an MK3 or MK3S, check the Belt Status numbers via LCD menu -> Support -> Belt Status. Check the tension of your beltsĬheck your belt-tension. A loose pulley is usually the main cause of staircase layer shifts.īoth pulleys on both axes also have to be aligned, meaning the motor pulley has to be well centered and the belt has to be moving in a straight line, not traveling from right to left while the pulley is turning. Both grub screws need to be tight, one of them has to be tightened against the flat part of the motor shaft. Make sure the X and Y motor is tightened in the motor mount, that the pulley (orange arrows in the picture below) is secured on the motor shaft and aligned with the pulley on the opposite end, and that the pulley can move freely. In general, Super-lube or any other multi-purpose grease will do as well. Another good lubricant is the Mogul LV 2-EP. According to our testers, the best lubricant is a homogeneous, soft grease with lithium additives, such as the GLEIT-µ HF 400. You can read more about in i3 Printer Regular Maintenance and this guide.Īlso, verify if the smooth rods don't bear any deep scratches and if the bearings are properly lubricated. See the photo below and make sure the cables are arranged accordingly. If the cables hit the frame before the extruder assembly does (if it's an MK3) or before the X end-stop does (if it's an MK2/S or an MK2.5) the printer detects an inaccurate end position.

REPETIER SERVER PRUSA I3 MK3 ZIP

For example, there might be a piece of filament stuck around the belt (usually around the Y-axis pulley) from your previous prints.Īnother instance of obstruction is when the zip ties or another part of the extruder cable bundle are not arranged according to 5. Make sure there are no obstructions in the path of the extruder or heatbed and their bearings. Make sure the extruder and the heatbed can move freely Also, note that in Stealth mode, the Crash detection feature is not available. For bigger or more complex prints, the Normal mode is recommended.

The stealth mode is perfect for small and simple objects. You can change Power mode in the LCD Menu -> Settings -> Mode. Run the printer in Normal mode rather than in the Stealth mode.

REPETIER SERVER PRUSA I3 MK3 PC

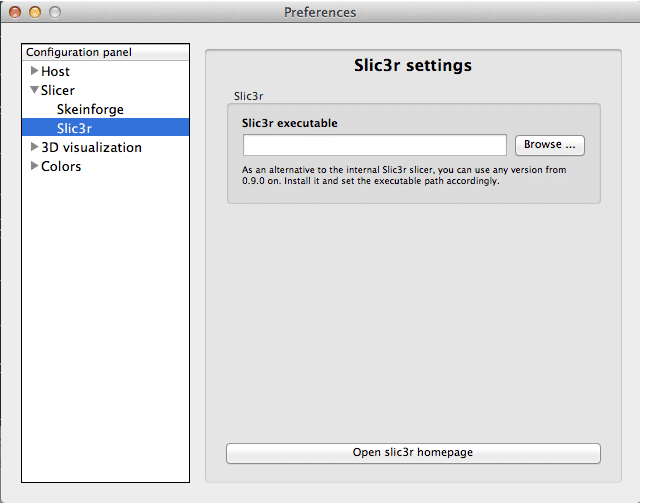

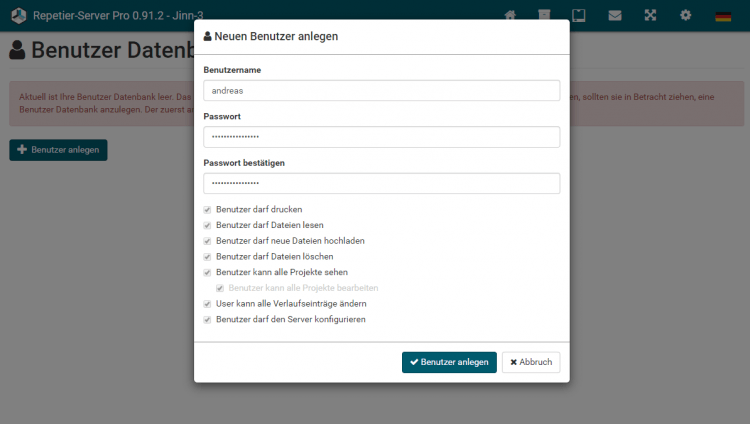

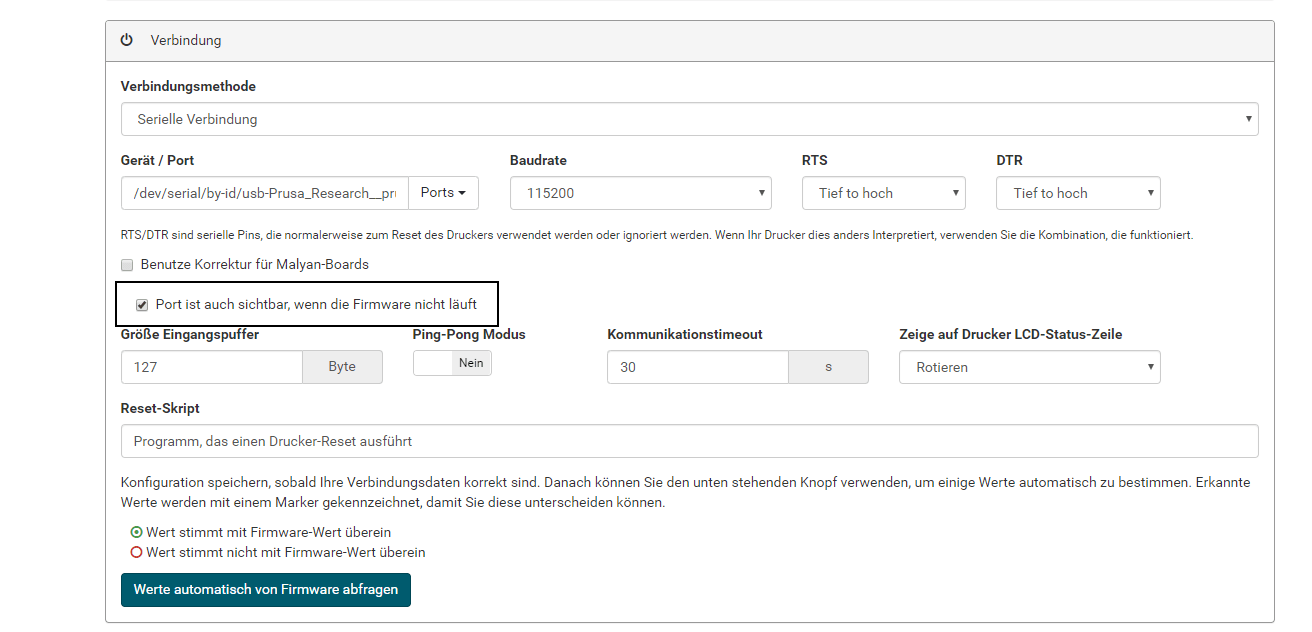

Just connect the printer to your PC via USB and start Pronterface.Prusa i3-series Check your printer’s power mode I need an interactive console to let me read values of stepper motor parameters, change & save. I'm printing technical parts that requires some degree of accuracy: screw holes, bearing seat block and such where 0.1mm difference matters.īy the way, I think there's a way to send g-code in Prusa Slicer but that's not going to work for my purposes. Please help pointing me in the right direction. Repetier sees it (USB-to-serial port becomes available) but couldn't establish a working connection to the point I can use the console. On the Prusa i3Mk3 I couldn't seem to connect it properly to Repetier. M92 (enter new parameter for each stepper motor) On my other 3D Printer I would connect them to a Repetier server and in it there's a console that lets me send G-Code commands: Posted by: printed 20x20 test cube and the print was off-measurement.

0 kommentar(er)

0 kommentar(er)